Outer Packing Test

Container Desiccant Outer Packing

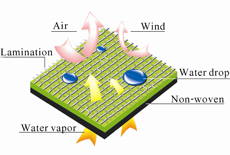

Simple test of air permeability and water repellence upon outer package

Simple test of air permeability:

Put some CaCl2 in flake or granular into a small bag made of laminated non-woven, heat sealed. A few days later, CaCl2 turns into liquid. It proves that the material has good air permeability.

Pay special attention to anti-leakage capacity of the package of container desiccant:

* Simple test of water repellence upon outer package:

Seal a bag made of outer package, with water inside, hoisting for 1 month. No water leakage is found. Or seal a glass tightly with a piece of the material of outer package, with 2/3 glass of water inside, inverting the glass on an absorbent paper. After three days, the absorbent paper remains completely dry. The tests prove that the material is extremely reliable anti-leakage capacity.

Truly qualified package of container desiccant requires not only has good air permeability, but also have reliable ability of anti-leakage. For a lot of the desiccant products in the current market, their package materials have merely air permeability, but no anti-leakage ability. After desiccant adsorbing, moisture vapor condenses into liquid water, which escapes through the package and drops down to the goods. As a result, the goods is not being protected, but in fact being damaged. It brings big loss to the consignors or consignees!

Chinese

Chinese English

English