wrapping film

Stretch film,Air-Care is also called Wrapping film .It is widely used in the pack fields of chemical products, electronic products, ceramic, machinery equipments etc. In recent years, the consumption of stretch film is increasing rapidly.

Our Stretch film is made of polyethylene and other special accessory ingredients. It has high clarity and glossiness, excellent strength, outstanding puncture resistance, unrivaled toughness, good stretchability. It is non-smell, Non-toxic and can be packed directly for foodstuff.

Pre-Stretch film & Hand Stretch film

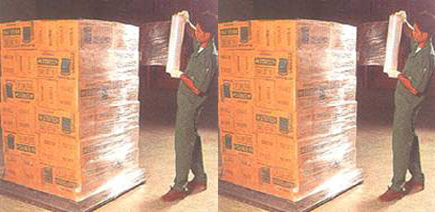

Hand Stretch film:The hand wrapper is the simplest implement for Conventional Hand-Stretch film wrapping. The film is mounted on a frame where unwinding of the film can be slowed down by turning a handle. This is to allow a certain degree of stretch control.

There is a great variety of specs of hand stretch film in different width and thickness. Generally, it is 15μm-50μm in thickness, with different tensile strength.

Pre-Stretch film is designed for conventional stretching, and is a technique where the actual stretching is performed between the pallet load and the film roll. The stretch force is generated by the turntable carrying the pallet load.

The machine has stronger pulling force, so Pre-Stretch film is thicker. Hand stretch film is too weak and easily broken for machine stretch. In order to have a nice wrap, it is recommended to use the specifications specially matching the machine.

Application Fields:

Stretch film has the functions of moisture-proof, anti-dust, fastening, anti-lost for the packed cargo. It can be widely used on the pack for cartons, pallets, building materials, chemical fertilizer, cement, bulb, cloth, wheel hub, electronics, chemicals, machinery, fabrics, textile, paper making, furnishings, food packaging, can and bottle, glass and ceramic, resin material, kinescope, etc.

Key Benefits

1. Cargo Unitization:

This is one of the obvious benefits. With the wrapping strength and resilience, it can make small articles fastened into a whole, and will not be scattered under bad conditions. Thus, possible damages are avoided.

2. Primary Protection:

It provides the surface protection with a light, protective surrounding and realizes the function of dust-proof, oil-proof, moisture-proof, water-proof and theft-proof. Moreover, stretch film brings uniform forces to the cargo to avoid the damage. This advantage is the traditional packing material like strap, packing tape do not have.

3. Reinforcement

It brings the packed goods to a whole to save the occupied space, and to firmly fasten the goods with the pallets, so as to avoid the cargo’s moving during transport. Additionally, the adjustable tensile strength makes the hard products tight and soft products shrunk. It is particularly effective in the industry of textile and tobacco.

4. Cost Reduction:

Using stretch film pack , only costs15% of wooden case, 35% of hot retracted film, 50% of paper carton. Additionally, it reduces the labors and improves the packing efficiency.

Specification Tolerance and Technical Data(Standard GB10457)

| Variety | Width (mm) | Thickness(mm) | Intensity | ||||

|---|---|---|---|---|---|---|---|

| Spec | Tolerance | Tensile | Tolerance | Tearing Mpa | Elongation rate% | Toughness N/cm2 |

|

| Hand Stretch film | 450~500 | ±3 | 0.015~0.05 | ±0.004 | ≥15 | MD≥400 CD≥700 |

≥1 |

| Pre-Stretch film | 100~500 | ±3 | 0.015~0.05 | ±0.003 | ≥12 | MD≥300 CD≥500 |

≥1 |

* Diameter of paper core is 75mm.

Chinese

Chinese English

English